Key: test item, instrument name, total nonvolatile migration, gravimeter, moisture permeameter

Pharmacy Packaging Materials

Release time:

2021-08-05

Pharmacy is a very rigorous process. For pharmaceutical packaging, its purpose is not only to assist transportation and storage, especially the inner packaging material, the packaging material and packaging form can directly affect the quality of the drug.

With the introduction of a series of policies such as related review, the quality supervision of pharmaceutical packaging materials has become more and more important to pharmaceutical companies. Regulatory agencies have also taken corresponding measures to ensure the safety of the public's medication. The random inspection of drug packaging materials by each drug inspection unit is one of the effective measures.

In the spot check results, the water vapor transmission rate, oxygen transmission rate and non-volatile matter of pharmaceutical packaging materials are often unqualified test items on the list. The first two are collectively referred to as the barrier properties of the pharmaceutical packaging materials, which are important physical properties of the pharmaceutical packaging materials to block external humidity and oxygen, and to ensure that the drugs are not polluted or deteriorated by the environment; non-volatiles are the chemical properties of the pharmaceutical packaging materials themselves. Due to the contact between the medicine packaging material and the medicine, the substance of the packaging material itself will gradually migrate into the medicine, which affects the quality of the medicine.

To improve the quality of pharmaceutical packaging materials, pharmaceutical companies cannot rely solely on the quality control of the packaging material companies. Pharmaceutical companies themselves must also improve the quality control of pharmaceutical packaging materials and strengthen daily quality inspections. However, the testing instruments on the market are mixed, and some instrument manufacturers falsely respond to the experimental elements specified in the standard, and the data calculation formula specified in the standard is altered, resulting in users not being able to obtain the real data that meets the requirements of the standard, and the data that does not comply with the GMP. sex.

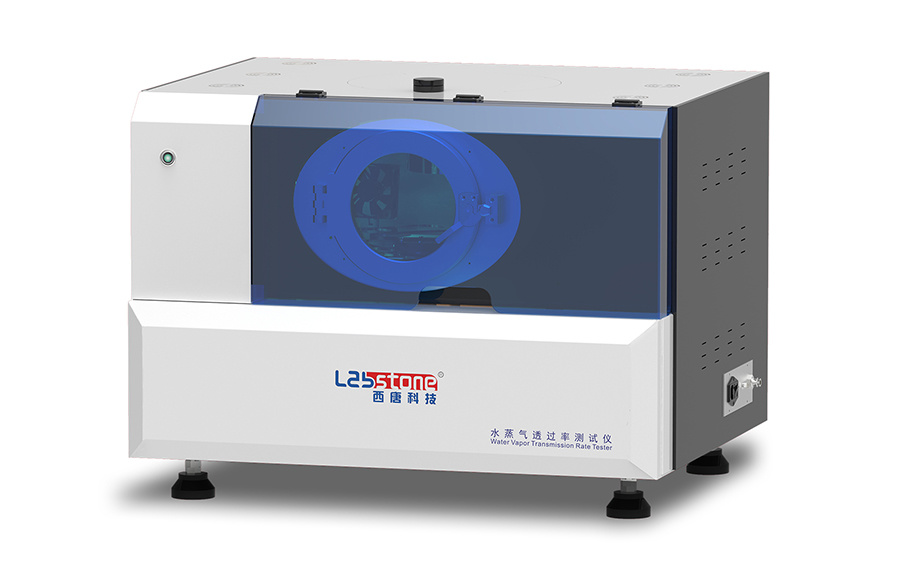

Xitang Technology has developed and produced the world's first water vapor transmission rate tester for weight increase and weight reduction in one cup method. The process data is consistent with the result data and conforms to the authenticity and consistency of the GMP data. It is a national standard material definite value equipment. ;

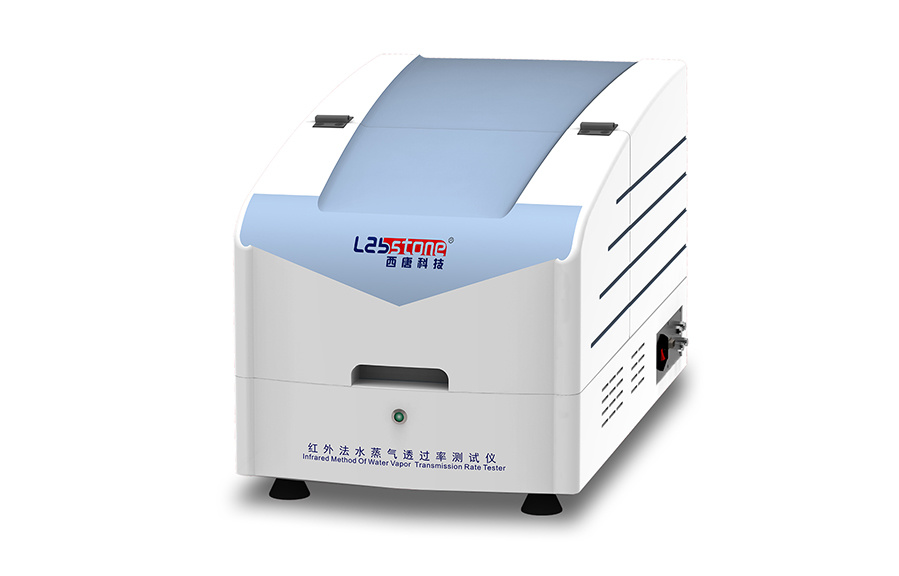

Introduce the technology of the Chinese Academy of Sciences and launch the infrared water vapor transmission rate tester equipped with TDLas laser technology, which does not attenuate and does not require regular calibration, and the long optical path light wave is more stable, and the technology surpasses many imported brands;

Electrolysis water vapor transmission rate tester equipped with self-developed micro-water electrolysis sensor. 10μm electrode distance, PPB level high precision, won the "Yunchuang Cup" 2020 Innovation and Entrepreneurship Competition Winner Award.

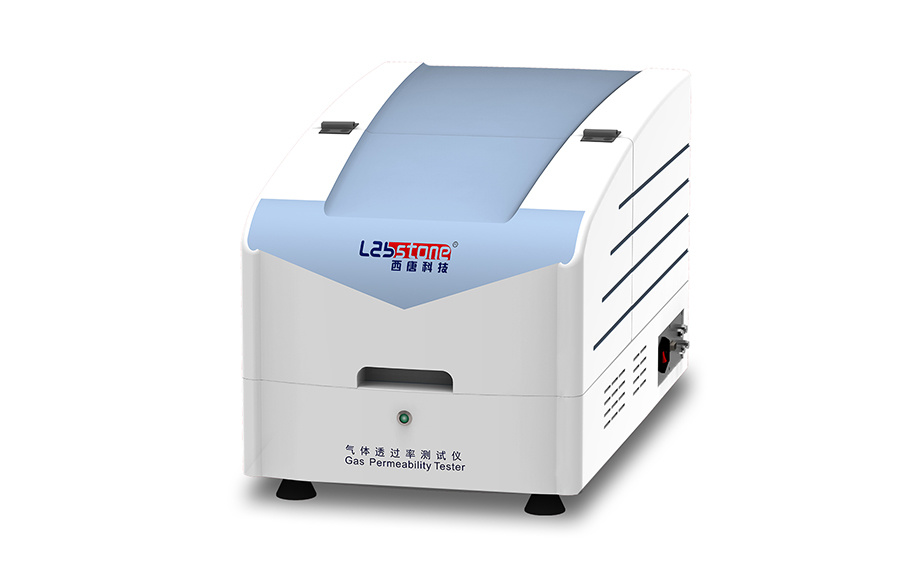

Patented pressure difference oxygen transmission rate tester without filter paper technology. The rapid 5-minute vacuum technology eliminates the influence of filter paper, and the accuracy is as high as 0.001cm/㎡*day, which is an order of magnitude more precise than traditional technology.

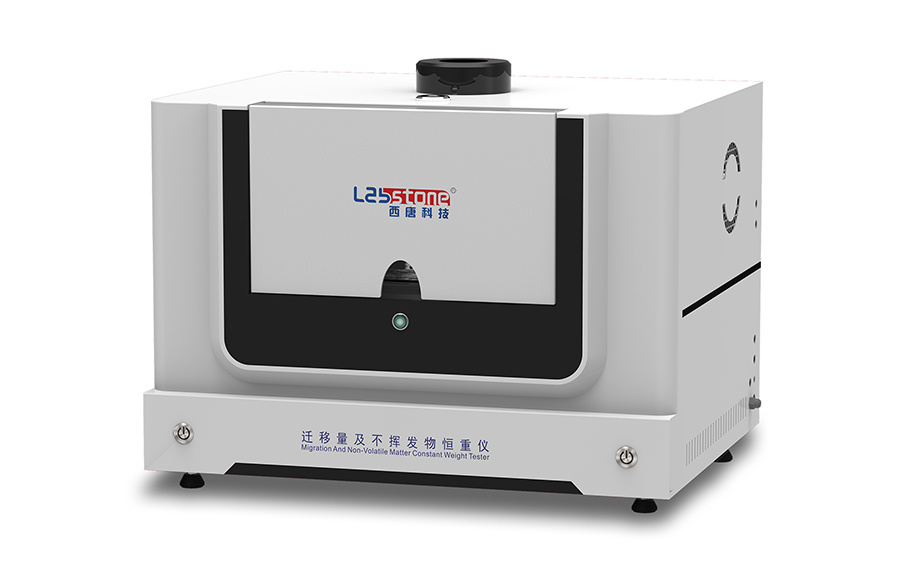

The patented non-volatile constant weight meter integrates water bath evaporation, heating and drying, drying and cooling, and constant temperature weighing. It replaces traditional water bath pots, ovens, drying ovens and balances. 2 processes complete 0.3mg constant weight weighing.

Xitang Technology is committed to packaging and material testing technology, and is willing to work with all friends to continuously improve the quality control of the industry.

Pharmacy Packaging Materials——Relative Products:

Previous

Next

Related Applications

Evaporating Residue, Non-volatile Residue

2021-09-01

Pharmacy is a very rigorous process, and the quality of water has a major impact on the quality of pharmaceuticals. Ordinary water contains many trace elements and other substances, which cannot meet the needs of pharmaceutical production. Only purified water that meets the requirements can be used in pharmaceutical production. In this regard, the state has formulated a number of testing items to monitor the quality of purified water, and "non-volatile matter" is the most "torturing" item. The "most tortured" person in non-volatile matter testing? According to the Pharmacopoeia, 100ml of purified water is placed in an evaporating dish with constant weight to evaporate to dryness, and after drying to constant weight, the remaining residue shall not exceed 1mg; in addition, according to the general requirements of the Pharmacopoeia, the constant weight needs to be dried twice and weighed. The difference is less than 0.3mg. The 0.3mg constant weight requirement is very difficult for manual operation, so too many experimenters always struggle with this, and they think that the non-volatile item is too torturous. How to solve this "torture" problem? In today's increasingly high degree of automation, Xitang Technology has given the answer-a non-volatile constant weight meter. The constant weight instrument developed and designed by Xitang specifically to meet the requirements of constant weight, integrates the functions of water bath evaporation, heating and drying, drying and cooling, and constant temperature weighing. Instead of traditional water bath, oven, drying oven and balance, 2 weighing processes can achieve constant weight weighing. It not only perfectly meets the requirements of the standard 100%, but also greatly improves the efficiency of constant weight and the accuracy of the experiment. At this point, the "torturing" experiment is no longer tortured, the experimenter only needs to install the sample, and the rest is handed over to the automation. At present, more than ten listed pharmaceutical companies have applied the constant weight instrument for quality inspection. The constant weight instrument in the pharmaceutical industry can also be applied to: non-volatile matter in extracts of pharmaceutical packaging materials, loss on drying of raw materials, extracts of traditional Chinese medicines, and other constant weight requirements experiments. Purified Water Non-volatile Residue Constant Weight Tester——Relative Products: Constant Weight Tester 12 specimens, integrated the functions of evaporating, heating, drying, constant temperature weighing. Constant Weight Tester 23 specimens, integrated the functions of evaporating, heating, drying, constant temperature weighing. Constant Weight Tester 48 specimens, integrated the functions of evaporating, heating, drying, constant temperature weighing. Constant Weight Tester 12 specimens, integrated the functions of heating, drying, constant temperature weighing.

Contact Us

Guangzhou Labstone Technology Co., Ltd

Add: 6 / F, building A1, No. 2-6, Jinbao Road, Baiyun Hubao street, Baiyun District, Guangzhou, Guangdong

Technical:020-86406337

Switchboard:020-86406230

Email:LabStone@vip.163.com

Message

fOLLOW