Key: test item, instrument name, total nonvolatile migration, gravimeter, moisture permeameter

Product

Trace Moisture Analyzer - Electrolytic Method

- Description

- Applications

- Standard

- Features

- Parameter

- Configuration

- Video

- PDF Download

-

- Commodity name: Trace Moisture Analyzer - Electrolytic Method

uW-E-100

Function

It is used to determine the water content of test samples, including high - molecular materials such as rubber particles, resin raw materials, melt - blown non - woven fabrics, desiccants, fibers, rocks, sutures, etc.

Working Principle

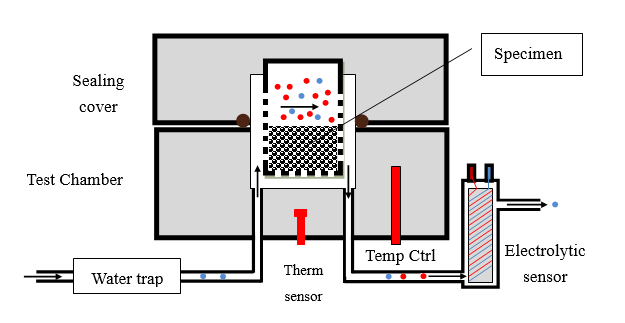

Electrolytic of water method.

The test sample is placed in a sealed constant - temperature test chamber. The water volatilized from the test sample is carried by dry nitrogen (carrier gas) to the micro - water electrolysis sensor. The sensor electrolyzes all the water in the carrier gas and calculates the water content of the test sample.

Compliance Standards

Electrolytic analysis method, including GB/T 22313 - 2008, ISO 15512:2019, ASTM D5460 - 02(2017), ASTM D6869 – 17, etc.

Product Features

- The electrolytic micro - water sensor enables absolute value measurement with high accuracy.

- Temperature control: It features parameterized settings, gradient heating, high accuracy, stability and reliability, and overload protection.

- Fully automatic: There are no mechanical knobs. It can be started with a single button and is fully intelligent throughout the process. Data can be saved in case of power failure.

- Error measurement: It can measure both systematic errors and sample - loading errors, and deduct systematic errors for precise measurement.

- Sample loading: It provides an alarm prompt for sample loading.

- Sensor protection: It cools and separates the polluting substances volatilized from the test sample to prevent them from entering the sensor.

- Self - detection of startup faults to avoid testing in a faulty state.

- Software: It offers graphical, full - process, and all - factor monitoring, along with multiple report formats.

- Optional: GMP "Computerized System" function module.

Technical Specifications

Name

Parameter

Name

Parameter

Water content

0~5%

Measurement error

1.22*10 - 3 ug / s

Sensor error

1ppmv

Electrolysis rate

3.68 ug / s

Sample capacity

10~12 ml (others need to be customized)

Sample-adding path diameter

<9mm (others need to be customized)

Temperature range

Room temperature to 300℃

Temperature control error

±0.5℃

Carrier gas type

99.999% high - purity nitrogen

Carrier gas flow rate

100 cm3/min

Working air pressure

0.1~0.2 MPa

Interface size

1/8 - inch metal tube

Power supply

AC 220/110V 50/60Hz

Power

<1800W

Dimensions (mm)

415(L)×720(W)×400 (H)

Net weight of the main unit (kg)

42

System Configuration

Main unit, test computer, professional testing software, Agilent water trap, nitrogen cylinder pressure reducer.

Items to be Prepared by the User

High - purity nitrogen, funnel, high - temperature gloves.

-

Function

It is used to determine the water content of test samples, including high - molecular materials such as rubber particles, resin raw materials, melt - blown non - woven fabrics, desiccants, fibers, rocks, sutures, etc.

Working Principle

Electrolytic of water method.

The test sample is placed in a sealed constant - temperature test chamber. The water volatilized from the test sample is carried by dry nitrogen (carrier gas) to the micro - water electrolysis sensor. The sensor electrolyzes all the water in the carrier gas and calculates the water content of the test sample.

-

Compliance Standards

Electrolytic analysis method, including GB/T 22313 - 2008, ISO 15512:2019, ASTM D5460 - 02(2017), ASTM D6869 – 17, etc.

-

Product Features

- The electrolytic micro - water sensor enables absolute value measurement with high accuracy.

- Temperature control: It features parameterized settings, gradient heating, high accuracy, stability and reliability, and overload protection.

- Fully automatic: There are no mechanical knobs. It can be started with a single button and is fully intelligent throughout the process. Data can be saved in case of power failure.

- Error measurement: It can measure both systematic errors and sample - loading errors, and deduct systematic errors for precise measurement.

- Sample loading: It provides an alarm prompt for sample loading.

- Sensor protection: It cools and separates the polluting substances volatilized from the test sample to prevent them from entering the sensor.

- Self - detection of startup faults to avoid testing in a faulty state.

- Software: It offers graphical, full - process, and all - factor monitoring, along with multiple report formats.

- Optional: GMP "Computerized System" function module.

- The electrolytic micro - water sensor enables absolute value measurement with high accuracy.

-

Technical Specifications

Name

Parameter

Name

Parameter

Water content

0~5%

Measurement error

1.22*10 - 3 ug / s

Sensor error

1ppmv

Electrolysis rate

3.68 ug / s

Sample capacity

10~12 ml (others need to be customized)

Sample-adding path diameter

<9mm (others need to be customized)

Temperature range

Room temperature to 300℃

Temperature control error

±0.5℃

Carrier gas type

99.999% high - purity nitrogen

Carrier gas flow rate

100 cm3/min

Working air pressure

0.1~0.2 MPa

Interface size

1/8 - inch metal tube

Power supply

AC 220/110V 50/60Hz

Power

<1800W

Dimensions (mm)

415(L)×720(W)×400 (H)

Net weight of the main unit (kg)

42

-

System Configuration

Main unit, test computer, professional testing software, Agilent water trap, nitrogen cylinder pressure reducer.

Prepared by the User

High - purity nitrogen, funnel, high - temperature gloves.

Keywords:

Related Products

undefined

Product Consultation

Contact Us

Guangzhou Labstone Technology Co., Ltd

Add: 6 / F, building A1, No. 2-6, Jinbao Road, Baiyun Hubao street, Baiyun District, Guangzhou, Guangdong

Technical:020-86406337

Switchboard:020-86406230

Email:LabStone@vip.163.com

Message

fOLLOW